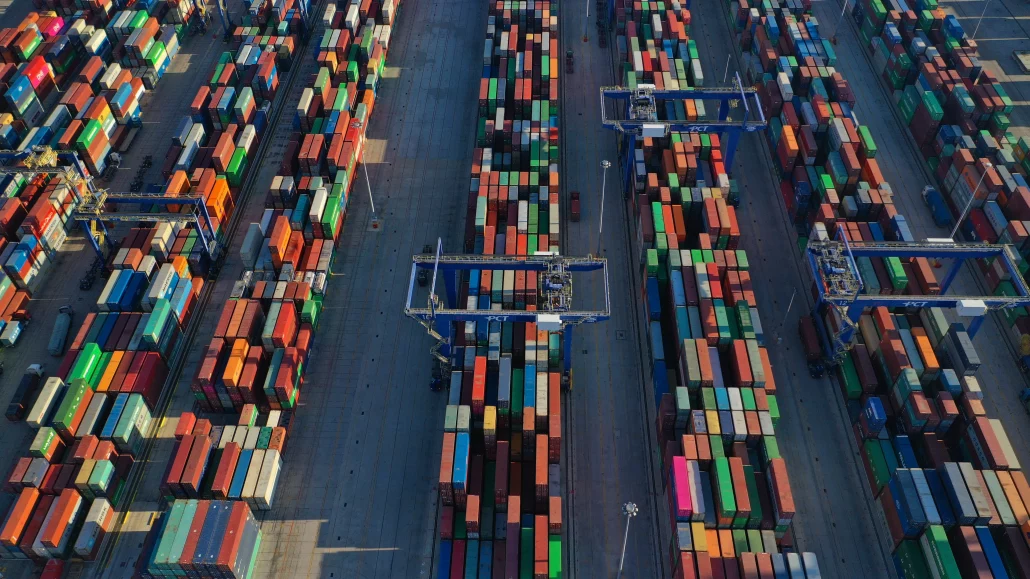

Global supply chain risks have become a major concern for businesses in today’s unpredictable environment. Disruptions caused by geopolitical tensions, economic shifts, and climate-related events can impact operations and profitability. To stay competitive, organisations need strategies that combine technology and proactive planning.

Understanding Global Supply Chain Risks

Global supply chain risks include delays, cost fluctuations, and compliance challenges. These risks arise because supply chains often span multiple regions and depend on complex networks of suppliers. When one link fails, the entire chain feels the impact. Identifying these risks early is the first step toward building resilience.

Strategies to Navigate Global Supply Chain Risks

Managing risks requires a mix of technology and process improvements. Here are practical strategies to consider:

- Digitise Core Processes: Automation reduces human error and speeds up workflows. Digital invoicing and order processing ensure faster approvals and fewer delays.

- Improve Visibility Through Integration: Connecting procurement, logistics, and finance systems creates a single source of truth. This transparency helps businesses respond quickly to disruptions.

- Leverage Predictive Analytics: Data-driven insights allow organisations to forecast demand and anticipate potential bottlenecks. Acting early prevents costly delays and stock shortages.

- Diversify Suppliers: Relying on one supplier increases vulnerability. Building a diverse supplier base spreads risk and ensures continuity during disruptions.

- Strengthen Compliance and Security: Global operations face regulatory challenges. Automated compliance checks and robust cybersecurity measures reduce exposure to legal and data risks.

Watch our video below:

The Role of Technology in Reducing Global Supply Chain Risks

Technology is the backbone of modern supply chain resilience. It does more than automate tasks and transforms how businesses anticipate, respond, and recover from disruptions. Here’s how:

- Real-Time Visibility: Digital platforms provide instant access to shipment status, inventory levels, and payment progress. This transparency allows businesses to act quickly when delays or shortages occur.

- Automation for Accuracy: Automated invoicing, order processing, and compliance checks reduce human error and speed up workflows. Because manual processes often cause delays, automation ensures smoother operations and fewer bottlenecks.

- Predictive Analytics: Advanced analytics tools use historical and real-time data to forecast demand and identify risks before they escalate. For example, predictive models can flag potential supplier delays or seasonal demand spikes, enabling proactive planning.

- Cloud-Based Collaboration: Cloud technology connects suppliers, logistics partners, and finance teams on a single platform. This integration eliminates silos and improves communication across global networks.

- Cybersecurity Measures: As supply chains digitise, protecting sensitive data becomes critical. Encryption, multi-factor authentication, and continuous monitoring safeguard systems against cyber threats.

Beyond solving problems, technology creates opportunities for efficiency, sustainability, and agility. Businesses that embrace these tools can turn global supply chain risks into a competitive advantage.

Where To Go From Here?

Global supply chain risks are inevitable, but they can be managed with the right strategies. By combining digitisation, analytics, and strong governance, businesses can turn uncertainty into opportunity. The future belongs to supply chains that are agile, transparent, and technology-driven.

Contact us to leverage on our decades of experience and solutions to help you with your long-term business goals and secure your future in a technology-focused future.